1. Background information

Lithium is the lightest metal in nature. It has unique physical and chemical properties such as high specific heat, high conductivity and strong chemical activity.

At present, the lithium resources that can be exploited and utilized mainly include rock lithium and salt lake lithium.

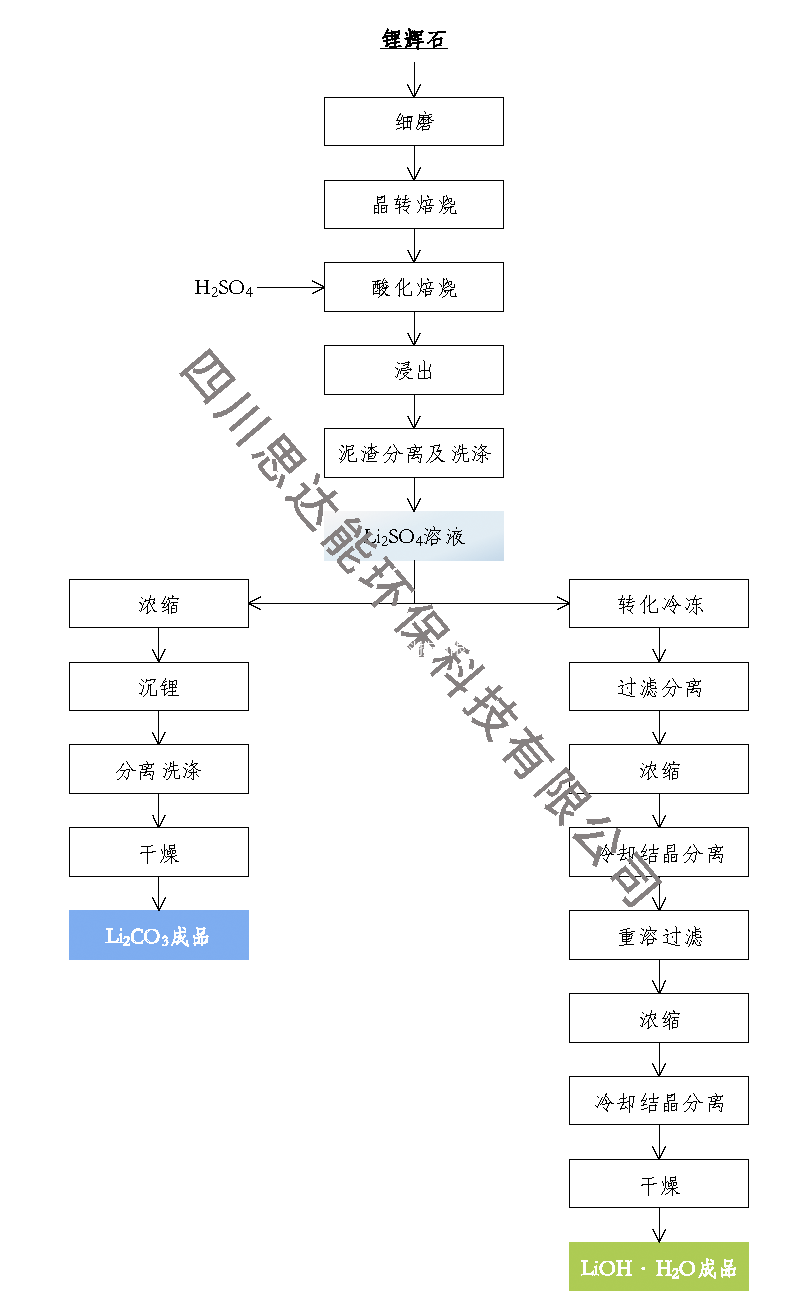

Although China is rich in salt lake lithium resources, it is difficult to extract lithium due to the high ratio of magnesium to lithium in salt lake brine, and the domestic ore lithium extraction process still occupies a dominant position.

Among many methods of extracting lithium from ore, sulfuric acid method has the characteristics of low energy consumption, small material flow and high production efficiency. Therefore, sulfuric acid method is still the main method of producing lithium products in China.

In the production process of extracting lithium by sulfuric acid method, a rotary kiln is used to separate lithium concentrate from α- Type calcination is converted into loose structure and easy to react β- In the process of crystal conversion roasting, a large amount of flue gas is generated at the tail of the rotary kiln, in which the dust concentration is usually 50 ~ 200g / Nm3, and contains nitrogen oxides, sulfides and other pollutants. With the implementation of major national decisions such as the blue sky defense war, the flue gas emission standards have been gradually tightened, and some enterprises are facing the upgrading and transformation of environmental protection standards.

2. Flue gas condition

Factors such as the difference of SO2 content in the flue gas produced by a rotary kiln and the actual content of fluoride in the flue gas produced by a rotary kiln are generally affected by the difference between 500 ℃ and 200 ℃, and whether the flue gas produced by a rotary kiln is generally affected by the difference of lithium and fluoride content:

Serial number | Index | Data | Company |

1 | Flue gas volume | 60000 | Nm3 |

2 | Temperature | 390 | ℃ |

3 | Dust | 120 | g/ Nm3 |

4 | NOx | 800 | mg/Nm3 |

5 | SO2 | 500 | mg/Nm3 |

3. Emission requirements

Serial number | Index | Data | Company |

1 | Temperature | 80 | ℃ |

2 | Dust | 10 | mg/ Nm3 |

3 | NOx | 50 | mg/Nm3 |

4 | SO2 | 20 | mg/Nm3 |

4. Technological process

If the dust content of flue gas is less than 10MN / m3 after special selection, the dust collection accuracy can reach 10MN / m3 after high temperature.

The clean flue gas after dust removal enters the SCR denitration reactor for denitration. The liquid ammonia is evaporated and gasified through the evaporator before being injected into the flue gas of the SCR system. The gasified ammonia is mixed with dilution air and injected into the flue gas upstream of the SCR reactor through the ammonia injection grid to produce a reaction under the action of catalyst to remove NOx.

The temperature of flue gas after denitration will be reduced to about 120 ℃ after heat exchange, and the waste heat will be recycled at the same time. After SO2 is removed from the flue gas by double alkali desulfurization method, it enters the flue gas desulfurization system.

5. Process advantages

1) The high-precision filter element with high temperature resistance (up to 700 ℃), corrosion resistance, oxidation resistance and vulcanization resistance is adopted, so that the system operates more stably and there is no risk of burning the filter bag;

2) Long service life and low operation cost, and the core filter material is guaranteed for 3 ~ 5 years;

3) The filtration accuracy (5mg / Nm3) is much higher than the existing emission standard, which meets the long-term requirements and enables the enterprise to have more lasting market competitiveness;

4) It can provide clean high-temperature flue gas, improve denitration efficiency and reduce operation cost;

5) The denitration efficiency is high, and the NOx emission concentration can be as low as 20mg / Nm3;

6) High activity catalyst can maintain NOx at a high conversion level, the ammonia escape concentration is less than 3ppm (V), and the conversion rate of SO2 / SO3 is controlled below 1%;

7) Provide high-temperature clean flue gas for waste heat recovery.

8) Wet desulfurization dual zone control technology is adopted to effectively reduce liquid gas ratio and energy consumption;

9) The desulfurization efficiency is high, and the emission concentration of sulfur oxide can be as low as 20mg / Nm3.

6. Industry case display

Take the tail gas treatment of a lithium salt kiln as an example:

號 | 參數(shù) | 指標 | |

1 | 進口參數(shù) | 進口風量 | 40000Nm3/h |

2 | 進口NOx濃度 | ≤500 mg/Nm3(標干,8%O2) | |

3 | SO2 | ≤400 mg/Nm3(標干,8%O2) | |

4 | 水蒸氣濃度 | ~20% | |

5 | O2 | ~8% | |

6 | 溫度 | ~300℃ | |

7 | 含塵濃度 | ≤100g/Nm3 | |

8 | 出口參數(shù) | NOx濃度 | ≤30(標干,8%O2)mg/Nm3 |

9 | SO2濃度 | ≤20(標干,8%O2)mg/Nm3 | |

10 | 含塵濃度 | ≤5mg/Nm3 | |